How NuMat is Engineering the Building Blocks of the Future, One Molecule at a Time

This article is part of a series about how OS Fund (OSF) companies are radically redefining our future by rewriting the operating systems of life. Or as we prefer to think about it; Step 1: Put a dent into the universe. And Step 2: Rewrite the universe. You can see the full OSF collection here and read more about Building a Biological Immune System.

In contemplating the future, I love imagining how our daily lives today will be thought of in the future. What appears sci-fi to us today but will be “normal” 50 years from now? What inefficient and boneheaded things do we do today that future generations will look back at and laugh?

Seeing beyond what’s possible is a rare skill. Being able to design and build beyond what’s possible is even more rare. Put together, this is the unique set of skills and abilities that OSF founders all have in common. Most importantly, they’ve chosen to focus their abilities on tackling the biggest problems humanity faces.

But who are they? What makes them tick? Why do this versus other things? And how might their technologies change the world? I set out recently to learn a little more about the companies I invest in. These are their stories.

NuMat

Tl; dr: Molecules are the building blocks of life, but thus far in human history we’ve only had a basic set to play with. This limitation has severely hampered our ability to innovate as a species. Being able to program and print new molecules opens up new worlds of possibility, in more ways than we can even imagine. NuMat is doing just that, pioneering the path to programming and printing molecules: it is manufacturing at an atomic level. As they scale their processes, the very notion that we live in a world with limited resources might, soon, be an outdated one.

I recently sat down with NuMat’s CEO Ben Hernandez, and CSO Dr. Omar Farha, to talk about what they’re excited about in life. Within 30 seconds of starting our conversation, Ben and Dr. Farha were pushing me to reconfigure my imagination toward a world where we can create a chunk of rare metal from seawater, extract rare gases from air or the ocean, or turn toxic waste into drinking water.

It’s not magic, they insist.

It’s the science of the future.

I. Next-Generation: Molecular Manufacturing

Molecules are nature’s building blocks. Every living thing on this planet is composed of them.

However, there are natural limitations to what we can do with them. First, classic chemistry limits what we can design and make. Second, up until now, we’ve only been able to play with what nature has given us. We haven’t had the tools that can do what nature can’t. (If molecules are nature’s Legos, then we want to not just be able to build, but to design new types of bricks and pieces.)

Many of our planet’s problems can be simplified around these building blocks:

(1) Some building blocks we need more of and there simply aren’t enough of them in nature. (For example, many gases, such as Xenon which we need for deep space exploration)

(2) Other building blocks we simply let go to waste because we don’t know how to harvest or recycle them. (For example, Carbon dioxide)

(3) And still others are toxic to us or our planet, and we haven’t yet found good ways to get rid of them (For example, spent nuclear-fuel rods)

Hernandez and Dr. Farha co-founded NuMat from a desire to rethink the scale of manufacturing. Rather than going for a big, expensive engineering solution, they believe the most civilization-threatening challenges we face are actually going to be solved at the smallest possible level.

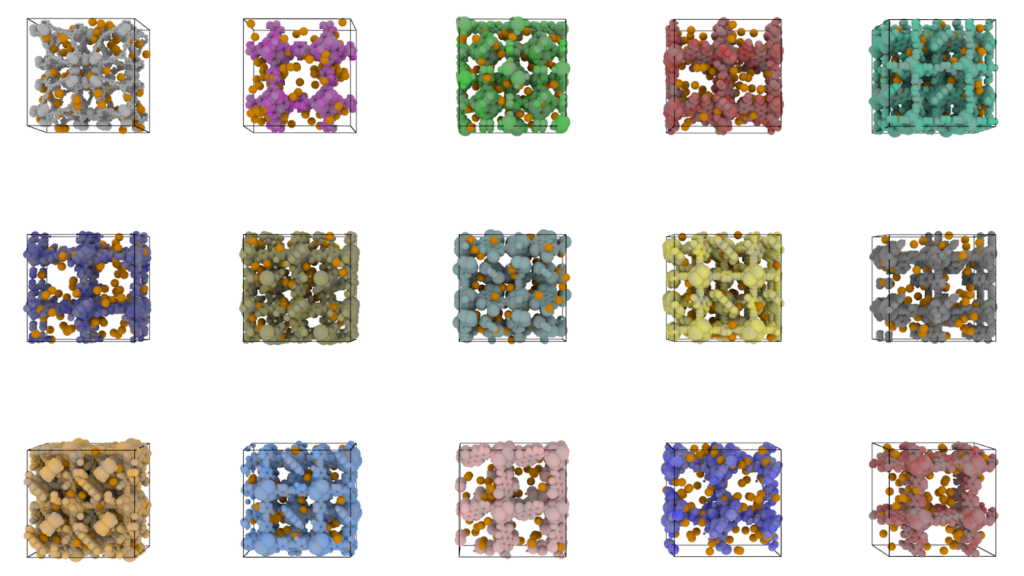

By using their state of the art, rapid prototyping software, NuMat has been working to create millions upon millions of hypothetical building blocks — that is, chemical structures and molecules and the things that house them — which would otherwise take scientists centuries to discover using old-school techniques.

“The future of manufacturing is building materials with utility at the molecular level,” Hernandez says. He hopes fighting over water will be another silly thing to look back on in the future.

Take, for example, Flint, Michigan, and the recent toxic water crisis. There are theoretical engineering solutions, like smarter, passive sensors that could detect and absorb toxic chemicals in the water.

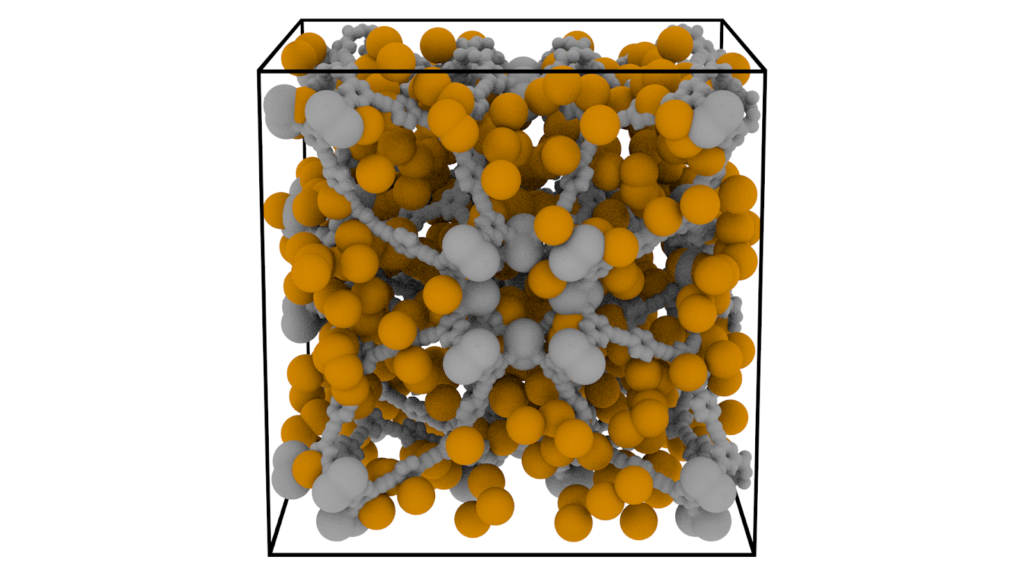

The proprietary technology pipeline they have at NuMat, centered on a technology called a MOF (Metal-Organic Framework), can be useful for applications like this once it reaches industrial scale.

In explaining the potential of MOFs — (rhymes with “mops”, just with an “f”) — to me, Hernandez said: “They’re almost like super Brita filters.” And Dr. Farha compared them to a sponge, which can suck up water, trap it, and keep the water in until you choose to squeeze it out.

Dr. Farha said a simple sponge is just the beginning.

The big question is: “Can you make smart, programmable materials that behave like sponges, selectively capturing targeted resources at the smallest possible level, and then release them on demand?” asked Dr. Farha.

“I believe that these materials will revolutionize the world in a good way. Helping us to live in a world which is cleaner and where growth is truly sustainable,” he added.

“Where we excel is identifying really unique ways to either harvest life-sustaining resources or to capture and destroy life-threatening ones at the smallest possible level,” said Hernandez. “We’re good at identifying which materials actually have a chance at solving these moonshot applications.”

II. Thriving in our Shared Future

The world is facing unsustainable population growth, with another two-to-three billion people walking this Earth over the next half century, leading to massive increases in resource consumption. By 2050, water consumption will have grown by 40% and a significant portion of the world’s population will not have access to it; food production may need to double, and there will be tripling in the demand for the raw materials and chemicals needed to build the megacities of tomorrow.

The implications of this are real and existentially threatening to mankind: pollution, extreme environmental stressors, inadequate food supply, insufficient energy, and geopolitical conflict.

While many governments, institutes, companies and individuals are committed to seeing a different future, the truth is that we need to innovate faster — much faster — and NuMat is poised to do just that.

Hernandez is asking the right questions: “How can we reduce the time to commercialization of foundational science from 30 years to just three or four?”

“True innovation is incredibly hard, as is bridging the gap between foundational science and product in order to solve the problems that matter.”

NuMat’s insight has been that they can dramatically decrease commercialization cycles while increasing the likelihood of success through the vertical integration of core capabilities — computational discovery through end product assembly.

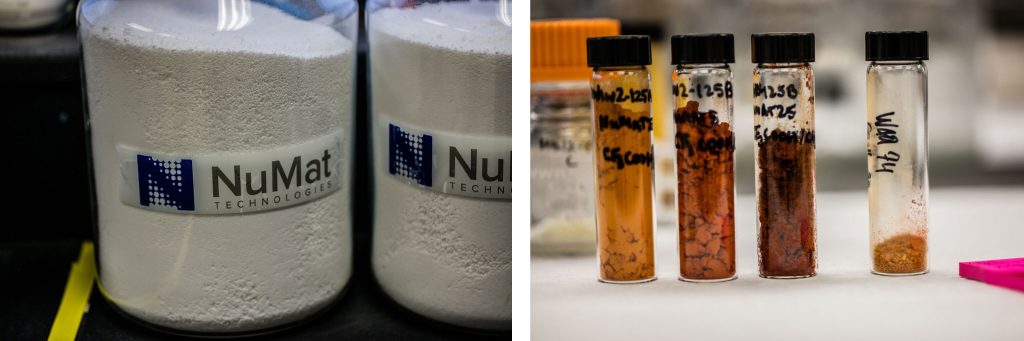

After using high-performance computing to hone in on their best bets for success, NuMat makes small quantities of MOFs, tests them, scales them, and then actually designs fully-engineered systems around those materials. On top of that, they assemble and manufacture those systems, delivering an integrated solution as opposed to just a material in a lab.

“This accelerated approach to application commercialization significantly reduces the time and costs of solving extremely complex moon-shot challenges, or alternatively, helps us get to ‘no’ faster, which is equally valuable,” said Hernandez.

III. The Ability to Filter Almost Anything

The solution for NuMat, and what differentiates Hernandez and his team from other MOF manufacturers, is their unique process which relies on “high-throughput experimentation” to essentially design novel materials, create massive databases of these materials, and then simulate how those materials would perform in certain applications before they ever make them in the lab.

But wait a second, I know what you might be thinking, based on the metaphors they used before: Filtering? Sponges? The future of humanity and our shared thriving depends on… kitchen tools?

Well, then they explained to me the first principles of why, yes, such tools are at the center of everything we will need to build the best future we can.

A simple way to think of MOFs is as a universal building block/Lego piece which could let any other number of pieces stick together. They can be built to grab onto and trap nearly anything molecular. This is especially useful for the storage, separation, and purification of anything from gases and liquids to chemicals, enzymes or drugs.

MOFs provide the scaffolding necessary to take chemical creations to the next level.

MOF research is one of the most exciting and most cited fields of chemistry in the past 10 years, and NuMat is one of the first companies in the world to commercialize them.

With NuMat’s novel, computing-focused workflow, the time and cost of commercial manufacturing cycles can be cut upwards of 90% in some instances.

“We design materials that intelligently sense and filter targeted gases and chemicals. This novel approach dramatically reduces costs, improves environmental performance, and enables form-factor innovation for a diverse range of consumer products and industrial processes,” Hernandez said.

IV. Real-World Examples

Here are a few more examples to demonstrate the potential of atomic manufacturing.

Example #1: Removing Salt From Water

By incorporating MOFs into filtration systems, engineers can lower the energy input required to perform reverse osmosis, which clears the salt out of water. With enough efficiency, this process becomes more feasible than importing freshwater, especially in areas where drinking water is already scarce. This would change the world. Earth’s freshwater resources are quickly dwindling as its population increases.

Imagine you were living in the desert and you had a portable MOF filtration system that you could simply run over night to procure all the drinking water you would need to survive the next day?

On an industrial scale, the possibilities are endless. Currently, desalination is so energy intensive it is mostly just military nuclear carriers (which have, basically, free energy) that desalinate at any useful scale.

Example #2: The “Gold” Hidden in Our Oceans

There is more lithium and uranium dissolved in ocean water than is thought to be presently available on land. Certainly, we could make use of it if we could extract it, which we should do regardless of whether or not we’re going to be drinking desalinated seawater. (Also, there is an estimated 20 million pounds of gold floating in seawater! So it’s not just metaphorical gold in those waters.)

Example #3: The Sky’s the Limit

NuMat can also design materials that can sense and capture CO₂. Power plants have started using filters to catch the CO₂ before it’s released into our breathing air, but here’s the unexpected twist: That CO₂ is valuable!

Right now, it gets tossed as a waste product. But it actually has a value in other contexts — for example, as a surgical gas which doctors can use to prevent inflammation that can damage tissue and harm patients.

This is a general strategy. Filtering is as much about resource extraction as it is about resource recycling, a hugely beneficial energy and efficiency boon. The recycling process that involves capturing and reusing filtered chemicals which would otherwise be discarded as waste is called a “closed-loop system”.

As Hernandez put it, it’s basically saying: “For whatever goes into something, how do you account for what comes out?”

“It’s not sexy, but the truth is that in any production environment — chemical production, electronics manufacturing, all these places — they take all these really high value, raw material inputs — exotic molecules, gases, and chemicals — and then they waste them, releasing them out of a smoke stack or an abatement unit.”

“I think the broader concept here is saying: ‘Can you design engineered systems where, at the smallest possible level, you’re doing work to harvest and recycle key inputs that are really valuable?’”

In theory, devices using MOFs could scrub CO₂ from power plant exhausts to be recycled for other beneficial users.

But why not think bigger?

Today, there are already several cities, especially in the developing world and China, where the air is completely unbreathable. As Hernandez explained, it’s possible to design materials that could be integrated into fabrics, clothes, gas-masks, air filters, and more, where over time you’re passively cleaning up the air, making it much safer for people to live in heavily polluted places.

V. The Real Sci-Fi Stuff: Unlimited “Limited” Resources

“There are all kinds of really valuable resources that are present in really small levels, in air, in water. And these are key for humanity to have access to these precious and scarce resources for us to continue to grow,” Hernandez says. “To conceptually think about how can you have the technology that creates something from nothing is really interesting.”

Consider xenon, a dense noble gas which naturally occurs in the Earth’s atmosphere in trace amounts and is mainly used for lighting in cars today. Old-fashioned science says the cost/benefit analysis doesn’t make it worth including in new inventions. But over at NuMat, they’re asking themselves: Can we design a material that can harvest xenon in a passive way to create a supply which is 100 times the amount currently available?

“A universal property of gases is that they like to stick to surfaces, like the birthday balloon you rub on the wall and it sticks,” Hernandez says. They can use this property to their advantage. With MOFs, instead of having to highly compress gases, which traditionally has required a massive energy input, NuMat can create surfaces, like little pockets, where gases can go in and stick to the walls.

If they figure out filtering and storage, the impossible would become possible. First step: deep space exploration. Xenon is the preferred propellant for NASA ion drives, but there isn’t enough of it! (From Wikipedia: “Xenon is inert, environmentally friendly, and less corrosive to an ion engine than other fuels such as mercury or caesium.”)

Hernandez explained even further: “The challenge is that if NASA, for example, was to do just one test mission — not even deep space — using xenon as a gas source, they would consume over a double digit percentage of the world’s annual supply, fundamentally disrupting that market. According to a report, a 10-ton xenon propellant load, which is about one mission, is greater than 10% of the global annual production rate of xenon. So there’s not enough of that really valuable, rare gas present to enable deep space exploration, let alone commercial opportunities.”

There is an estimated 2×1012 kg of xenon in Earth’s atmosphere, and according to this NASA talk, xenon can be used for: “lighting, detectors, plasma displays, lasers, dark matter research, anesthesia, and electric propulsion.”

(Yes, anaesthetic. Xenon is both rocket fuel and bio-compatible — clearly some sort of super molecule — and the gas is a promising anesthetic, possibly the best we’ve ever had.)

“The gifts of the atmosphere are plentiful, giving mankind new sources of prosperity and welfare. (…) even if the art of engineering accounts for but a small share in the overall bounty of riches the atmosphere has to offer, these additional products must still be embraced as the new treasures of the atmosphere.”

Carl von Linde, 17 December 1907

Because MOFs can harvest xenon from air, perhaps the sky is no longer the limit!

Or if that’s too sci-fi to contemplate, MOFs can work with existing travel options too. Hydrogen fuel cells have been on the brink of practical use for at least a decade now, but as Hernandez explains: “In order for people to start using hydrogen, you have to package it in a way where it doesn’t explode.”

Because of the lower pressure conditions required for storage, MOFs can help pack hydrogen safely and make clean energy vehicles safer and lighter.

VI. The Future of Medicine

The beauty of molecular manufacturing is that they can be as useful in exploring not only outer worlds, but inner as well.

Because MOFs can capture and filter out certain molecules, we could hypothetically use them to catch and deliver proteins or enzymes into the body. Think of it like FedEx for any drug.

They could even be programmed, to act only at specific sites in cells or bodies. Because MOFs are porous, they could be designed to travel to specific places in the body and stick there, with timed-release payloads, like a Trojan Horse. They could become a universal, biological delivery system.

Imagine a single company making the box, the cargo, and the delivery.

What might they deliver? Currently, for example, there is no way to deliver insulin orally to treat diabetes; insulin won’t last. But if you can create a MOF to embed the insulin and release it once it gets to the blood rather than in the gut, we would be able to control the slow release of these small molecules for the first time. The same could be done for oral administration of other drugs or vaccines. You could even use MOFs in bandages to time-release nitric oxide to speed up the body’s natural wound healing abilities.

This is why filtering is so cool. It is everywhere.

And just like how MOFs can trap a molecule of uranium in one million molecules of water, they could in theory, trap one drop of poison in your blood, allowing for detection. This could be as useful for forensic science as for medical science.

In the future, we’ll for sure laugh about how we used to think about 20th-century medicine. They did what, with how much!?!

VII. The People

Curious about how Hernandez and Dr. Farha found MOFs, I inquired about what led them to science and MOFs.

Dr. Farha was wowed by MOFs during graduate school, he said, after immigrating from Palestine as a teenager and working his way up from a full-time job in a taqueria while attending community college. He is now a professor of chemistry at Northwestern University. MOFs were so exciting because they are the only class of materials, he said, that could one day be in cars (hydrogen storage), help bring clean drinking water to the harshest desert environments (filtering), and spare humanity exposure against all kinds of toxic gases or health hazards.

We depend on clean air and water to live and will continue to depend on it long into our future.

“If you live in the desert, you should be able to make a gadget filled with these materials that could harvest water from just a small amount of humidity, capturing at night and releasing during the daytime. And in that case, you could a have clean, sustainable water source without digging a well. This is where the future is going — using molecularly engineered materials to sustainably harvest life sustaining resources in the harshest of environments,” he said.

For Hernandez, his story began decades before MOFs were even invented. As a child, he spent summers working at his family’s small coffee bean plantation in Mexico.

“We bought coffee from small growers, cleaned it, and reprocessed it to resell to larger distributors. At the end of each day, they would put the raw coffee beans on a huge table. My job was to pick out the rotten or deformed beans and put them in a separate bag. At the end of the day, they would weigh the bag and I’d get paid based on the weight of how many bad beans I’d pulled out, enabling us to resell the purchased beans for a higher value. Beyond teaching me the value of hard work, it was a manual lesson in how to increase the value of raw materials by removing impurities ” said Hernandez.

Recycling. Filtering. It was all there, in one story!

To think, he started on coffee, but one day, along with Dr. Farha, might be filtering every molecule on the planet.

Share

Return to News